I’m in Princeton, a sleepy mountain town in western Canada, known for its slogan, ‘Where rivers and friends meet.’ It also happens to be home to what might be the largest legal pharma-grade shroom farm in the world.

In a nondescript blue warehouse, behind a tall security fence, sits Optimi Health—a psychedelics manufacturer aiming to help the world heal by getting everyone heroically high.

On the other side of a walk-in vault, around 200kg of vacuum-packed psilocybin mushrooms are stored in boxes that tower all around me. It’s a staggering amount of psychedelic fungi to see in one place, a haul that includes strains like Chode Wave, Golden Teacher Infinity, and Albino Penis Envy. There is enough magic mushroom here to power over 5,000 trips.

There are also 1,000 doses of pure MDMA chilling in a fridge in the corner.

Just being in the vault feels trippy, like some hallucinogenic residue in the air is starting to weave its spell. However, for the farm’s head of mycology Scott Marshall, it’s just a normal day at work. He is one of a select number of ex-underground mushroom growers to have become a licensed psilocybe cultivator in North America, after laws controlling the use of psychedelic fungi were eased after decades of murderous, futile drug war.

Scott moved to Princeton for the job, and has become so obsessed with his lab work that he hasn’t left town in over a year. “I’m not trying to be ‘Mr Mushroom,’ but when I got hired they were like, ‘We need to fill this vault,’ so I did it,” he tells VICE. “It’s a dream come true. It’s going to have a super therapeutic effect on the world.”

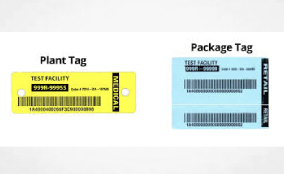

The journey a mushroom must take in order to get into this vault—which is licensed to hold up to $36 million worth of product—starts in a Petri dish. Marshall introduces mushroom spores of compatible mating types to each other and they fuse together, starting their own network of fungi. “It’s microscopically hot,” he said in a previous interview of the initial spore rendezvous. He then performs a few tweaks so that the mycelium develops as quickly as possible, before mixing it all into a liquid inoculate.

Marshall injects the concoction into a giant bag of rye grain, which consumes the mushroom water before being transferred into a sealed grow “bin,” where it eventually blooms into shrooms.

Then he does it again. And again. And again. It’s not easy work, and it’s paramount to avoid any contamination. The mishandling of mushrooms could open the door to unwanted microorganisms that could rip through the entire facility, wreaking millions of dollars worth of havoc.

The company’s operation could have been much more straightforward: Many mushroom companies just produce pure psilocybin through chemical processes in the lab. Others simply grow mycelial grain and sell it packaged as mushrooms. But Marshall believes that the botanical route, to organically grow real mushrooms, is more beneficial.